Pooling System Business

- HOME

- Business Field

- Pooling System Business

Pooling System Business

Experience the Top-Tier logistics service leading business innovation.

Sheet Pool System

The sheet pool system is a collaborative logistics equipment-sharing system for multi-level storage in canning/bottling companies and beverage/alcohol companies.

By supplying optimized sheets according to specifications, the system ensures product stability and reduces the cost of disposable packaging materials, and also introduces standardized logistics equipment. The sheet pool system is a logistics system that meets customer needs while fulfilling the social responsibility of environmental protection through the introduction of standardized logistics equipment and a shared cleaning system.

Download

Sheet Pool System

Operation Method

KPP

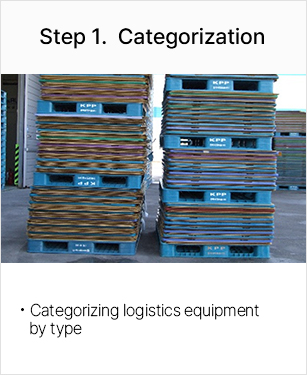

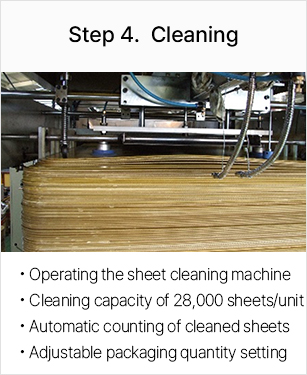

Logistics Equipment Sorting/Cleaning/Packaging

- Four dedicated logistics centers operated in Jincheon, Sejong, Yangsan, and Asan

- Categorizing, cleaning, and packaging tasks performed for each type of logistics equipment

- Automated cleaning machines operated for each type of logistics equipment

- Cleaning capacity: 10,000 sheets/hour (operating 10 cleaning machines)

Canning/Bottling

Product loading using logistics equipment

- Logistics equipment used for CAN/PET/Glass Bottle lines

- Sheet insertion requested based on product type, packaging products used based on quantity

- Palletizer used with an automatic sheet supply device

- Loading → Transportation → Banding → Wrapping → Dispatch

Beverage/Alcohol Companies

Product injection/logistics equipment storage

- Input of empty bottles and cans by the production line

- Automatic loading of sheets into sheet loading container after using depalletizer

- Storage of logistics equipment in separate storage areas after use

- Collection of logistics equipment from designated dedicated logistics centers for each actual demanding site after product delivery

Advantages

- We resolve the issues of purchasing costs, supply, and quality management of logistics equipment in the canning and bottling industry through standardization and specialized management of logistics equipment for PET and glass bottles and cans.

- We supply high-quality logistics equipment, including reusable standard-sized pallets, sheets, top boards, and other specialized equipment, with a specialized cleaning process, ensuring client trust and satisfaction.

- We provide support in constructing logistics centers in optimal locations through location analysis to minimize or reduce additional operating costs, thus facilitating cost efficiency in operations.

- We can supply logistics equipment to the desired specifications. Starting from 1,440x1,130, we can develop products according to customer preferences, such as 1,300x1,100, 1,200x1,000, 100x1,100, and 1,100x900, continuously improving service satisfaction.