For Transportation

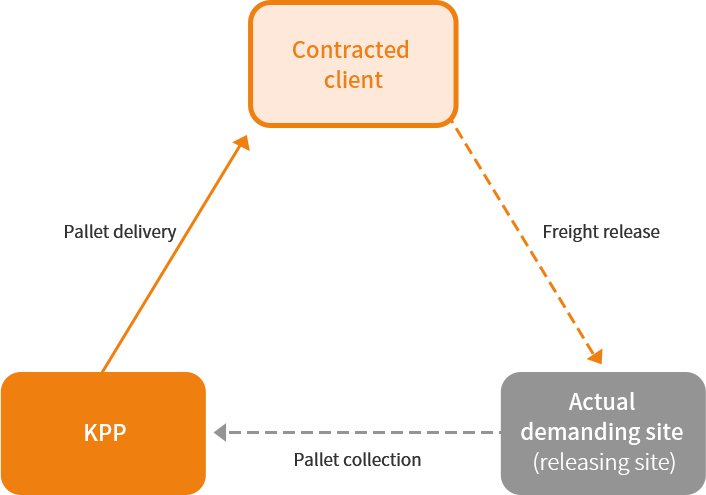

Pooling system, where KPP collects and manages pallets shipped from the contracted client to the trading partner

[Process]

-

Pallet Delivery

KPP delivers pallets quickly and accurately according to the contract conditions. Sturdy and well-maintained high-quality pallets are selected and provided to the contracted client.

-

Freight Release

The contracted client loads the freight onto the pallets delivered by KPP and delivers them to the actual demanding site. The shipment information is provided to KPP to ensure that the pallets can be collected from the actual demanding site.

-

Pallet Collection

Based on the shipment information provided by the contracted client, KPP directly collects the pallets from the actual demanding site. The pallets are cleaned, repaired, and stored in dedicated logistics centers for reuse.

For In-House Use

The pooling system in which pallets are used for product loading and storage purposes within the contracted client and then returned to KPP

[Process]

-

Pallet Delivery

KPP delivers pallets quickly and accurately according to the contract conditions. Sturdy and well-maintained high-quality pallets are selected and provided to the contracted client.

-

Pallet Return

The contracted client loads the pallets with freights and keeps them stored within their premises. Once the pallets are no longer needed, they are returned to KPP. The returned pallets are cleaned, repaired, and stored in dedicated logistics centers.